Digital Linear Heat Cable is brilliant in its simplicity.

Digital LHD cables typically consist of two metal cores covered by a temperature-sensitive material. When the temperature rises to a predefined point, the temperature-sensitive material melts, allowing the cores to come into contact and create a short circuit. This short circuit triggers an alarm signal to a fire alarm control panel or other monitoring device.

Patol Digital Linear Heat Cable available from G2 Fire comes with FRPE LSOH sheath. FRPE LSOH refers to a type of cable jacket material that is both Fire Resistant (FRPE) and Low Smoke Zero Halogen. This means the cable sheath is designed to resist fire propagation, minize smoke emission and avoid the release of toxic halogen gases during a fire.

Non-Resettable digital linear heat cable with black Nylon outer sheat, set to alarm temperature of 70 degrees Celsius. Available in 100m, 200m or 500m rolls.

Non-Resettable digital linear heat cable with black Nylon outer sheat, set to alarm temperature of 90 degrees Celsius. Available in 100m, 200m or 500m rolls.

Non-Resettable digital linear heat cable with violet Nylon outer sheat, set to alarm temperature of 90 degrees Celsius. Available in 100m, 200m or 500m rolls.

The End of Line Termination helps monitoring of the line and provides an industrial enclosure for housing the end of line resistors, which each line will need.

In conjunction with the EOL Termination box this interface helps monitor the linear heat cable line.

Linear heat detection (LHD) cable is commonly used in various applications requiring fire detection along a specific length, particularly in areas with harsh environments or where traditional detectors are impractical. It’s found in tunnels, warehouses, industrial settings, and even specialized areas like conveyor belts, cable trays, and tank farms.

Optical beam smoke detectors are best suited for large, open areas with high ceilings, where standard point detectors might be impractical or ineffective.

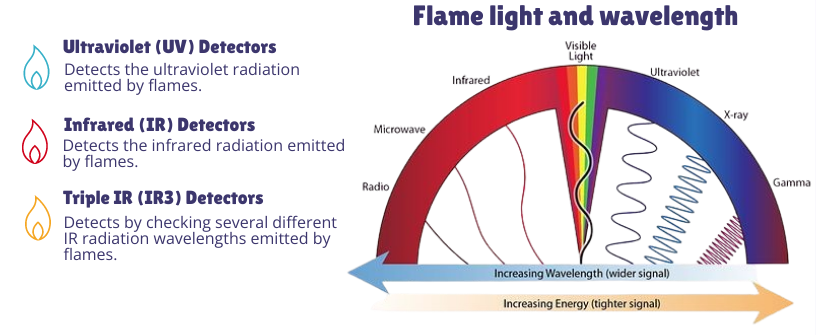

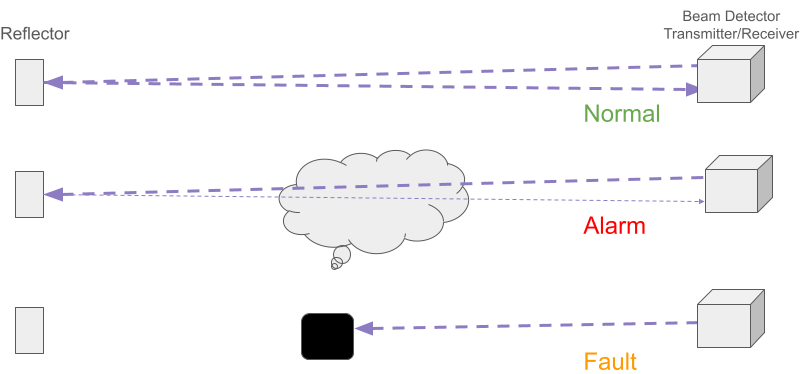

Optical beam detectors function by transmitting a beam of infrared light across a space and monitoring the amount of light received back. When some etners the beam’s path, it scatters or obsorbs the light, reducing the amount received by the detector. This reduction in light intensity is what triggers an alarm.

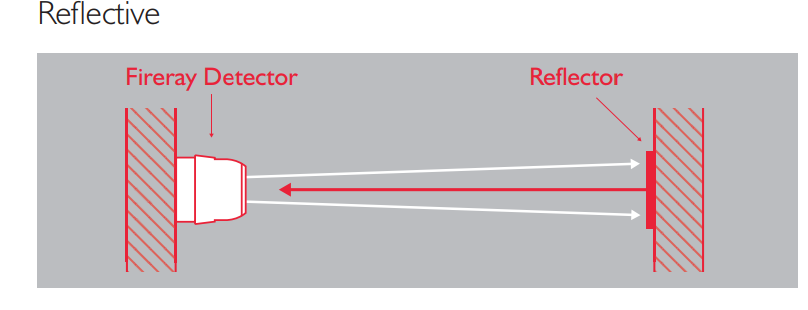

Transmitter and receiver are mounted in the same housing, and the beam is directed at a specially designed reflector, mounted at the opposite end of the protected area.

Transmitter and receiver are mounted at either end of the protected area. These beams are less popular as they are generally more expensive.

Fireray One auto-aligning reflective beam detector. Easy setup means quick installation. Available in 50m or extended range to 120m coverage.

EN54 approved conventional reflective beam detector, working from 8m to 100m. Easy setup with laser alignment tool built in and dip switch settings.

Reflective beam detector with Bluetooth connectivity to an app for configuration. Up to 160m coverage range.